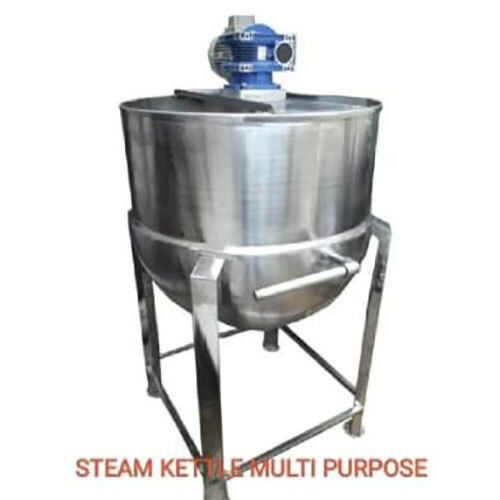

Ghee making kettle

Price 98000 INR/ Number

Ghee making kettle Specification

- Feeding System

- Manual

- Phase

- Single & Three Phase

- Automation Grade

- Semi-Automatic

- Machine Type

- Kettle

- Power Source

- Electric/Steam

- Speed Mode

- Variable

- Features

- Jacketed Heating, Tilting Arrangement, Insulated Body

- Function Type

- Heating, Melting, Mixing

- Noise Level

- Low

- Operating Temperature

- Up to 110C

- Heating Method

- Steam/Electric

- Frequency

- 50 Hz

- Product Type

- Ghee Making Kettle

- General Use

- Ghee Production in Dairy Industry

- Material

- Stainless Steel 304

- Type

- Ghee Kettle

- Capacity

- 100-500 Litre

- Weight (kg)

- 180-320 Kg

- Product Shape

- Round Kettle

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Electric Control Panel

- Installation Type

- Floor Mounted

- Voltage

- 220 - 440 V

- Power

- 4-6 kW

- Dimension (L*W*H)

- 1200 x 900 x 1200 mm

- Raw Material

- Milk/Butter

- Feature

- Stainless Steel Construction, Easy Cleaning

- Color

- Silver

- Manufacturing Standard

- GMP/ISO Compliant

- Temperature Indicator

- Digital/Analog Thermometer

- Applicable Industry

- Dairy, Food Processing

- Steam Pressure

- 2-3 Bar (for steam models)

- Cleaning System

- CIP (Clean in Place) Compatible

- Agitator Type

- Anchor with Scraper

- Mobility

- Mounted on Castor Wheels (optional)

- Discharge Valve

- Butterfly Valve SS

- Inner Finish

- Mirror Polished

- Outer Finish

- Matte Finish

- Kettle Lid

- Stainless Steel Hinged Lid

- Safety Feature

- Over-temperature Protection, Emergency Stop

Ghee making kettle Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- Delhi, Haryana, Jammu and Kashmir, Rajasthan, Uttar Pradesh

About Ghee making kettle

We are manufacturer of Ghee making machine and plant full setup from mini,semi-automatic to fully automatic setup every type as per requirnment and customer budget can be operated on gas,diesel and electric operated

and also steam operated running on wood boiler,diesel boiler,gas boiler,electric boiler

capacity starts from 100ltr-2000ltr as per requirnment

wide range of models are available with best quality which are manufactured by a knowledge, experienced and skilled labourers,these have minimal maintenance cost, operate with diesel gas for electric with very less fuel consumption and water consumption clean entirely and thoroughly with good pressure, These tested with every aspect and then supplied

Features

1)easy to install

2)very less water consumption

3)very less fuel consumption

4)can be used to do multiple works

5)clean process

6) environment friendly

7)low budget cost

8) excellent life

9) latest technology

10)easy to operate

11)no requirement of skilled labour for using these

we make customized too

For any requirement please contact

9999022825

9315340602

7042170080

Address-

Plot No. 9, Bajri Industrial Area, Dabua Pali Road, Gulmohar Garden, behind Bharat Petroleum, Faridabad, Haryana 121004

Advanced Design for Efficient Ghee Production

This ghee kettle features a polished stainless steel body with a hygienic round kettle shape, crafted for seamless melting, heating, and mixing. The jacketed heating allows for both steam and electric power sources, accommodating different processing setups. The agitator with integrated scraper prevents material build-up, ensuring consistent texture and preventing product burning, while the digital/analog thermometer and safety features provide precise control and peace of mind.

Superior Cleaning and Safety Standards

Built to meet GMP and ISO standards, this kettle incorporates Clean-In-Place (CIP) compatibility for effortless cleaning without dismantling. Over-temperature protection, an emergency stop, insulated body, and floor-mounted stability secure both operators and products. Its hinged stainless steel lid and butterfly valve facilitate safe, convenient discharge and access, upholding efficiency and workplace safety.

FAQ's of Ghee making kettle:

Q: How does the Ghee Making Kettle maintain consistent heating during production?

A: The kettle utilizes a jacketed heating system compatible with both steam (2-3 bar) and electric sources (4-6 kW), providing even and adjustable temperatures up to 110C. The anchor agitator with scraper ensures uniform mixing and prevents scorching, while the digital or analog thermometer allows for continuous temperature monitoring.Q: What materials can be processed in this ghee kettle?

A: This kettle is designed primarily for converting milk or butter into ghee. Its stainless steel 304 construction ensures compatibility with dairy products, maintaining product purity and preventing contamination throughout the ghee-making process.Q: When should the cleaning process be performed, and how is it managed?

A: Cleaning should be conducted after every batch or production cycle to maintain hygiene. The kettle supports Clean-In-Place (CIP) systems, enabling internal washing without disassembly, which streamlines routine maintenance and ensures compliance with food safety regulations.Q: Where can the ghee kettle be installed and used?

A: The kettle is suitable for floor-mounted installations within dairy plants and food processing facilities. Optional castor wheels provide mobility for flexible plant layouts. Its robust construction and insulated body make it ideal for industrial environments seeking efficient ghee production.Q: What benefits does the kettle's construction and design provide?

A: Stainless steel 304 construction ensures durability and food safety. The mirror-polished interior and matte exterior support easy cleaning, while the insulated jacket, digital temperature controls, and over-temperature protection contribute to product quality, operational safety, and energy efficiency.Q: How is manual feeding and agitation handled during operation?

A: Ingredients like milk or butter are manually introduced via the hinged lid, and the semi-automatic control panel governs mixing and heating. Variable speed settings allow operators to adjust agitation according to batch requirements for optimal texture and yield.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ghee Line - Ghee Kettle Category

gravy machine

Price 34000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Gravy Machine

Warranty : 1 year

Color : Other, Silver

Ghee Line - Ghee Kettle

Price 170000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Product Type : Ghee Boiler

Warranty : 1 year

Color : Other, Silver

ghee making kettle

Price 145000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Product Type : ghee making kettle

Warranty : 1 Year

Color : Other, Gray

Ghee boiling machine

Price 106000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Product Type : Ghee boiling machine

Warranty : 1 Year

Color : Other, Gray

Send Inquiry

Send Inquiry