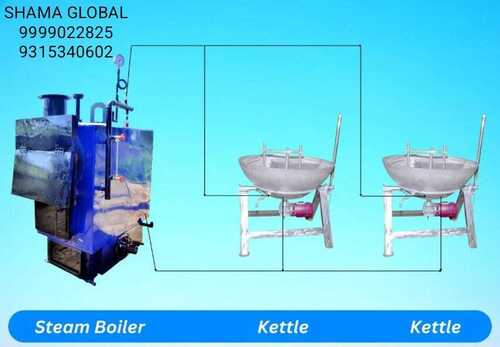

Steam Operated khoya making machine

Price 245000 INR/ Number

Steam Operated khoya making machine Specification

- Product Type

- Steam Operated Khoya Making Machine

- General Use

- Khoya (Mawa) manufacturing, dairy processing

- Material

- Stainless Steel (Food Grade SS 304)

- Type

- Automatic, Batch Type

- Capacity

- 100 to 500 Liters per batch (as per model)

- Weight (kg)

- 300-800 kg (depending on capacity)

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual & Semi-Automatic controls

- Processing Pressure

- Steam operated, pressure typically 4-7 kg/cm

- Cleaning System

- Removable pan, easy to clean

- Cooling Mode

- Ambient cooling after processing

- Sterilization Method

- Steam sterilization

- Motor Power

- 1 HP to 3 HP (as per model)

- Voltage

- 220-240V, Single Phase & 415V, Three Phase (depending on motor)

- Dimension (L*W*H)

- Approx. 1600 x 1300 x 1200 mm (varies by capacity)

- Feature

- Steam jacketed double layer pan, tilting mechanism, robust construction

- Color

- Silver (Polished Stainless Steel)

- Pan Thickness

- 3-5 mm (Food Grade SS 304)

- Application

- Sweet shops, dairy plants, food processing industry

- Temperature Control

- Thermostatic steam valve (optional)

- Heating Source

- External steam boiler (not included)

- Noise Level

- Low operational noise

- Safety Features

- Pressure release valves, heat-resistant handles

- Mounting

- Heavy-duty legs with anti-slip pads

- Tilting Mechanism

- Manual or motorized (customization available)

- Design

- Compact, ergonomic body, minimal heat loss

- Corrosion Resistant

- Yes, highly resistant to rust/corrosion

- Suitable Fuel for Boiler

- Coal, wood, diesel, gas (as per steam generator)

- Product Discharge

- Easy tilting/Pouring for complete discharge

- Maintenance

- Low maintenance, simple design

Steam Operated khoya making machine Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 10-15 Days

- Main Domestic Market

- Delhi, Haryana, Jammu and Kashmir, Rajasthan, Uttar Pradesh

About Steam Operated khoya making machine

We are manufacturer of khoya/mawa making machine plant full setup from mini,semi-automatic to fully automatic setup every type as per requirnment and customer budget can be operated on gas,diesel and electric operated

and also steam operated running on wood boiler,diesel boiler,gas boiler,electric boiler

capacity starts from 100ltr-10,000ltr as per requirnment

Rasgullah ball making machine,fryers,milk boiling machine,steam plant,musta machine

wide range of models are available with best quality which are manufactured by a knowledge, experienced and skilled labourers,these have minimal maintenance cost, operate with diesel gas for electric with very less fuel consumption and water consumption clean entirely and thoroughly with good pressure, These tested with every aspect and then supplied

Features

1)easy to install

2)very less water consumption

3)very less fuel consumption

4)can be used to do multiple works

5)clean process

6) environment friendly

7)low budget cost

8) excellent life

9) latest technology

10)easy to operate

11)no requirement of skilled labour for using these

we make customized too

For any requirement please contact

9999022825

9315340602

7042170080

Address-

Plot No. 9, Bajri Industrial Area, Dabua Pali Road, Gulmohar Garden, behind Bharat Petroleum, Faridabad, Haryana 121004

Efficient and Uniform Khoya Production

Utilize the steam-operated khoya making machine for consistent and high-volume khoya output ideal for sweet shops, dairies, and food industry applications. Its even heat distribution and thermostatic steam control (optional) minimize production loss, delivering smooth, authentic results for every batch.

Customizable Tilting and Robust Safety

Choose between manual or motorized tilting mechanisms to match your operational needs. Operator safety is ensured through integrated pressure release valves, heat-resistant handles, and stable, anti-slip mounting-making the discharge process simple and risk-free when handling large quantities.

Simple Operation and Hassle-Free Maintenance

The khoya making machine features a removable pan for easy cleaning and a design that keeps maintenance low. Whether using manual or semi-automatic controls, the streamlined process suits both seasoned operators and new users. Its corrosion-resistant stainless-steel body ensures long-term durability.

FAQ's of Steam Operated khoya making machine:

Q: How is the khoya making machine heated during operation?

A: The machine uses an external steam boiler (not included) as its heating source, operating at a pressure of 4-7 kg/cm2. The steam generated is circulated through the steam jacket, ensuring uniform heating throughout the pan.Q: What type of fuel is compatible with the steam boiler for this machine?

A: The external steam boiler can utilize coal, wood, diesel, or gas, depending on your steam generator's compatibility and availability of fuel at your location.Q: What are the benefits of using this khoya making machine for my business?

A: This machine offers uniform heating, high batch capacity (100 to 500 liters), low operational noise, and enhanced operator safety. The food-grade stainless steel construction ensures longevity and resistance to corrosion, making it ideal for continuous, commercial-level production.Q: How is the khoya or mawa easily discharged from the pan after processing?

A: An ergonomic tilting mechanism-available in manual or motorized versions-allows straightforward pouring and complete product removal, thereby reducing handling time and product loss.Q: What are the cleaning and maintenance procedures for this equipment?

A: The machine features a removable pan for easy cleaning and a simple, compact design that keeps maintenance requirements minimal. Routine checks for steam seals and valves ensure optimal performance.Q: Where can this khoya making machine be installed and used?

A: It is suitable for installation in sweet shops, dairy processing plants, and food manufacturing units across India and internationally, where high-quality khoya or dairy products are needed.Q: What safety measures are in place for operators?

A: Operator safety is ensured through the inclusion of pressure release valves, heat-resistant handles, anti-slip mounting brackets, and a strong, stable body design to prevent movement or accidental tipping during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam operated khoya plant Category

Steam Operated khoya plant

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Product Type : Steam Operated khoya plant

Color : Silver

Computerized : No

Send Inquiry

Send Inquiry