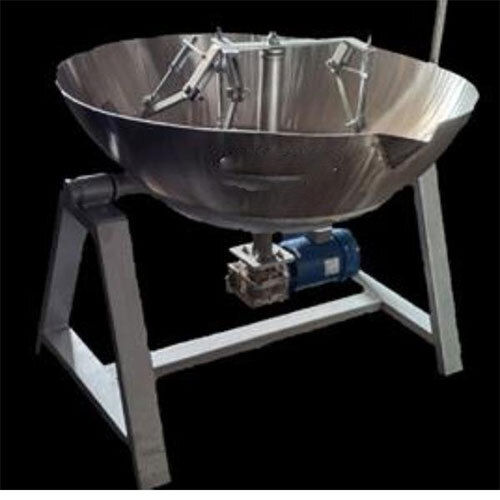

Khoya machine

Price 65000 INR/ Number

Khoya machine Specification

- Product Type

- Khoya Machine

- General Use

- Making Khoya, Mawa, Basundi

- Material

- Stainless Steel

- Type

- Automatic

- Capacity

- 80-120 Liters/Batch

- Weight (kg)

- 150 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual/PLC Based

- Processing Pressure

- Atmospheric

- Cleaning System

- Manual Wash

- Sterilization Method

- Heat Based

- Motor Power

- 2 HP

- Voltage

- 220-240 V

- Dimension (L*W*H)

- 1200 x 900 x 1200 mm

- Feature

- Heavy Duty Body, Easy Operation, Energy Efficient

- Color

- Silver

- Speed Control

- Variable

- Mobility

- Castor Wheels

- Finish Type

- Polished

- Power Consumption

- 1.8-2.1 kW

- Safety Features

- Overload Protection

- Application

- Commercial Dairy Processing

- Heating Mode

- LPG/Steam/Electric

- Batch Cycle Time

- 30-45 Minutes per Batch

- Bowl Material

- Food Grade Stainless Steel SS304

- Drum Thickness

- 3 mm

Khoya machine Trade Information

- Minimum Order Quantity

- 1 Number

- Main Domestic Market

- Delhi, Haryana, Jammu and Kashmir, Rajasthan, Uttar Pradesh

About Khoya machine

We are manufacturer khoya making machine which can run on gaselectricitywood and diesel and other options are by steam with wood boilergas boilerdiesel boiler or electric boiler

wide range of models are available with best quality which are manufactured by a knowledge experienced and skilled labourersthese have minimal maintenance cost operate with diesel gas for electric with very less fuel consumption and water consumption clean entirely and thoroughly with good pressure These tested with every aspect and then supplied

Features

1easy to install

2very less water consumption

3very less fuel consumption

4can be used to do multiple works

5clean process

6 environment friendly

7low budget cost

8 excellent life

9 latest technology

10easy to operate

11no requirement of skilled labour for using these

we make customized too

For any requirement please contact

9999022825

9315340602

7042170080

Address

Plot No 9 Bajri Industrial Area Dabua Pali Road Gulmohar Garden behind Bharat Petroleum Faridabad Haryana 121004

Exceptional Build for Commercial Performance

Engineered using high-quality SS304 stainless steel, this khoya machine ensures durability, hygiene, and longevity. The heavy-duty drum (3 mm thick) and polished finish support intensive use, making it ideal for commercial dairies and large-scale sweet production. Each batch cycle is completed efficiently within 30-45 minutes, ensuring optimal output to meet growing demands.

Flexible Heating and Control Options

Customize your operations with versatile heating modes: choose from LPG, steam, or electric. The Khoya machine is equipped with a variable speed motor and can be controlled using either a manual interface or a PLC-based system, allowing precise control and consistency in every batch. This adaptability makes it easy to integrate into various dairy setups.

Safe, Efficient, and Mobile Operation

Safety is prioritized with features like overload protection and atmospheric processing pressure. The planetary mixer is energy efficient, consuming only 1.8-2.1 kW per cycle. Mobility is enhanced by smooth-rolling castor wheels for easy movement. While cleaning is manual, the heat-based sterilization method ensures a hygienic process for all dairy products.

FAQ's of Khoya machine:

Q: How does the khoya machine operate in commercial dairy processing?

A: The khoya machine operates by automatically heating and mixing milk in its food-grade stainless steel bowl. Users can select LPG, steam, or electric heating based on site preference, and control the speed and cycle using manual or PLC-based controls, making it suitable for uninterrupted commercial production.Q: What are the primary applications of this khoya machine?

A: This machine is designed for making khoya, mawa, and basundi, serving commercial dairies and sweet manufacturers who require consistent, high-quality batch processing of dairy products.Q: When should I use the variable speed control feature?

A: Variable speed control allows adjustment of the mixing speed based on product type and consistency required. Use lower speeds for delicate textures and higher speeds for thorough mixing, optimizing product quality for each batch.Q: Where is this khoya machine commonly installed?

A: Typically, it is installed in commercial dairy plants, sweet shops, large kitchens, and food processing facilities across India, where high-volume and quality production of khoya-based products is essential.Q: What is the typical batch cycle time for this khoya machine?

A: Each batch takes approximately 30-45 minutes, depending on the heating mode and desired consistency, allowing efficient processing and rapid turnover in busy production environments.Q: How is the machine cleaned and sanitized?

A: The machine is manually washed after each batch, and features heat-based sterilization to ensure all food-contact surfaces remain safe and hygienic for continued operation.Q: What are the key benefits of using this automatic khoya machine?

A: Key benefits include rapid production cycles, variable heating options, robust construction, enhanced safety features, energy efficiency, and straightforward mobility enabled by castor wheels, all contributing to improved productivity and reliability in commercial dairy processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Khoya Machine Category

Khoya making machine

Price 74340 INR / Piece

Minimum Order Quantity : 10 Pieces

Computerized : No

Warranty : 1 Year

Material : Stainless Steel

Color : Gray

khoya machine

Price 90000 INR / Piece

Minimum Order Quantity : 10 Pieces

Computerized : No

Warranty : 1 Year

Material : Stainless Steel

Color : Gray

Vegetable Cutting Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Warranty : 1 year

Material : Stainless Steel

Color : Silver

Stainless steel 65ltr khoya making machine

Price 65000 INR / Piece

Minimum Order Quantity : 10 Pieces

Computerized : No

Warranty : 1 Year

Material : Stainless Steel

Color : Gray

Send Inquiry

Send Inquiry